Software laboratory complex for the simulation of laboratory work on the main sections of the course of building materials science for technical specialties. The program complex includes simulation labs:

The virtual laboratory practice is implemented in the form of graphical applications running under the MS Windows operating system.

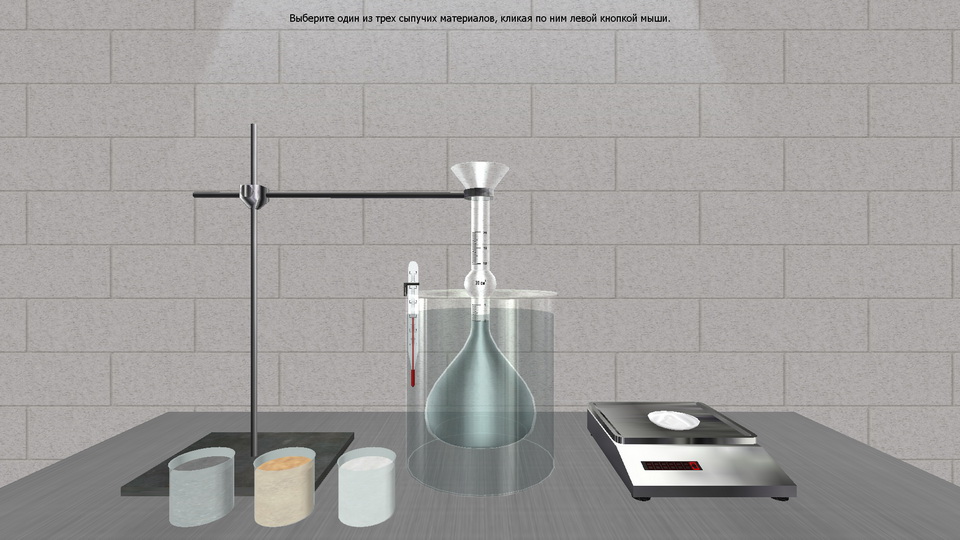

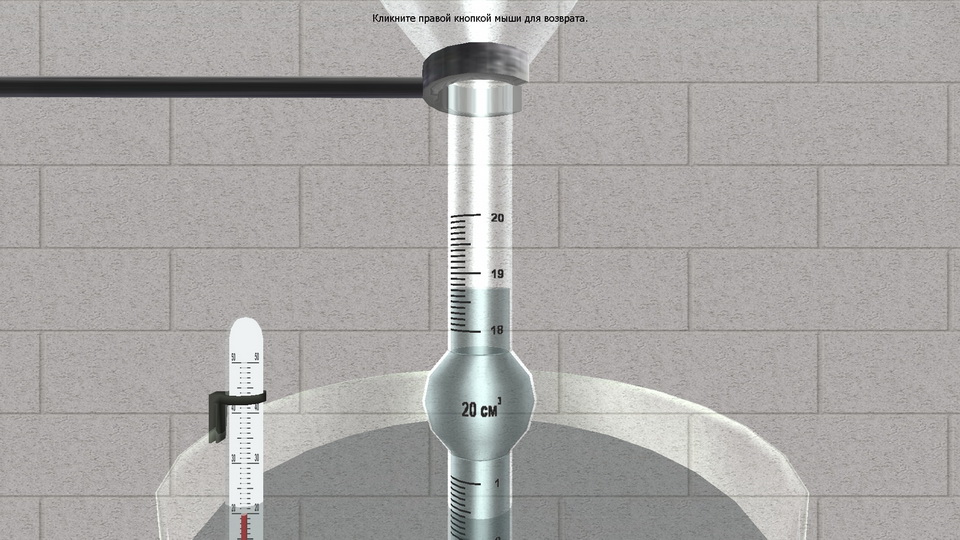

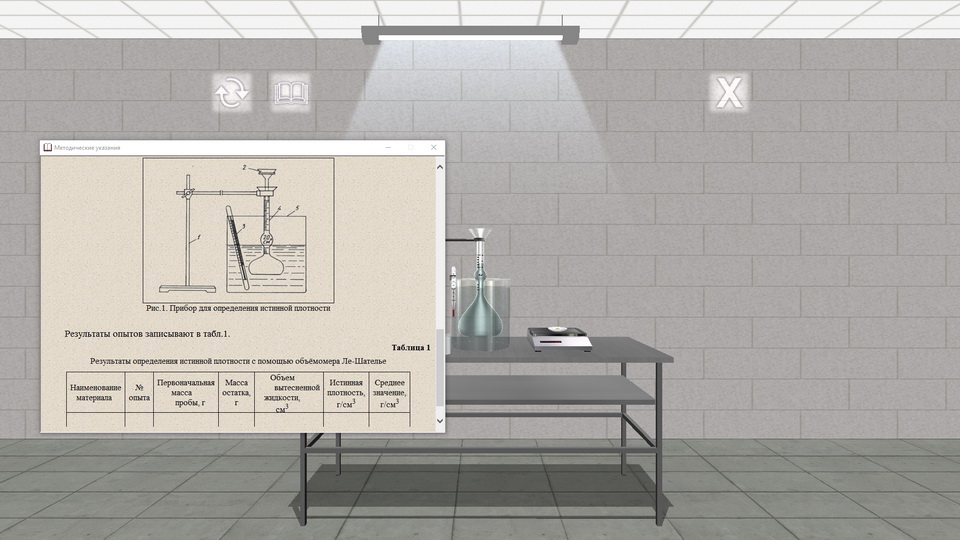

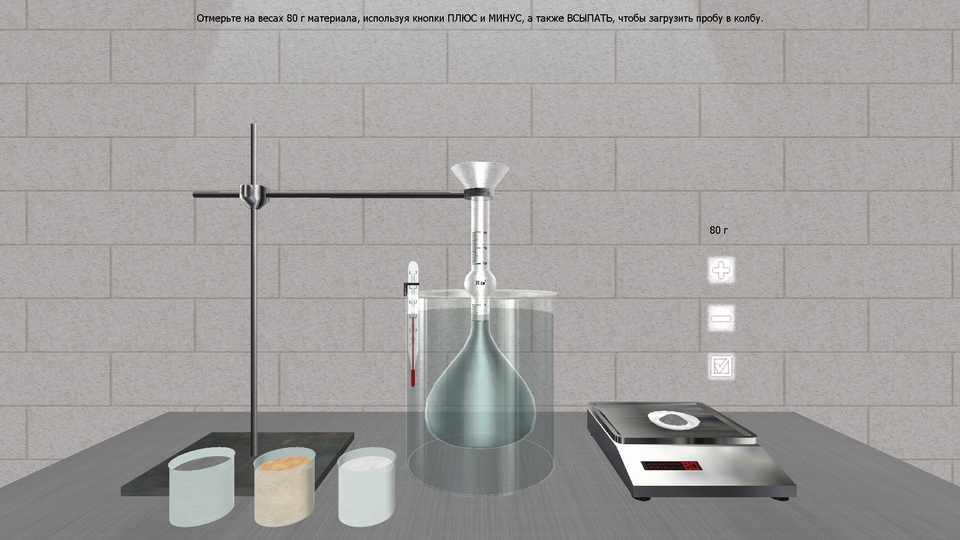

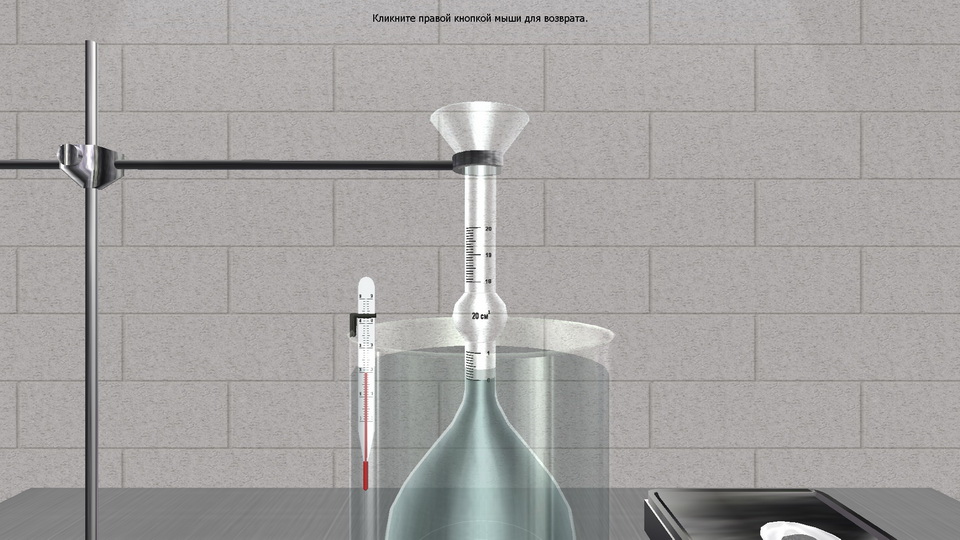

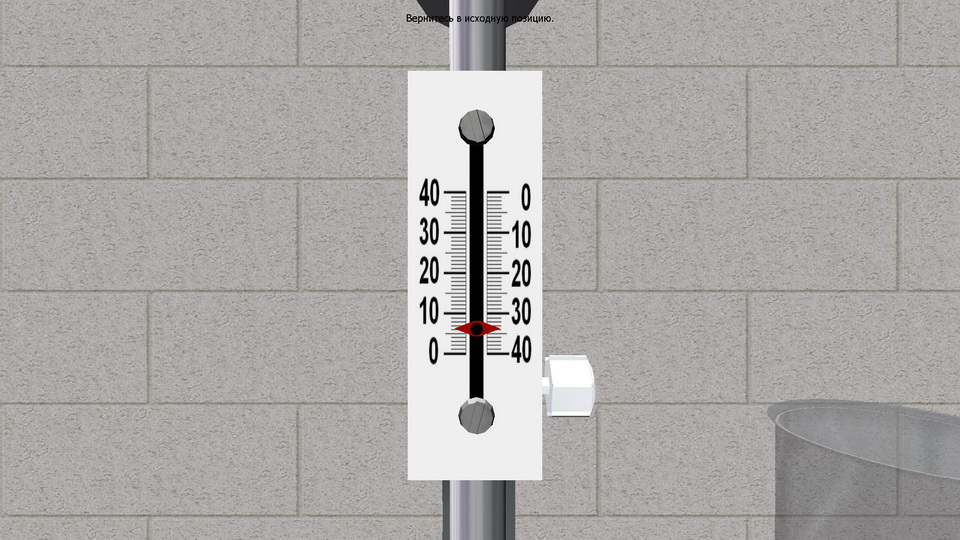

OBJECTIVE: The determination of the true density of the powder material using a special glass flask – Le Chatelier volume meter. SUMMARY: The main element of the laboratory setup is the standard Le Chatelier volume gauge. In the flask of the volume meter, there is an inert liquid in which a sample of the powdered material is placing. The volume of fluid displaced from the flask is measured. The input parameters of the simulation experience are: the type of building material (cement, sand, gypsum) and the mass of the experimental sample. The output data are: the mass of the sample residue and the volume of the displaced fluid.

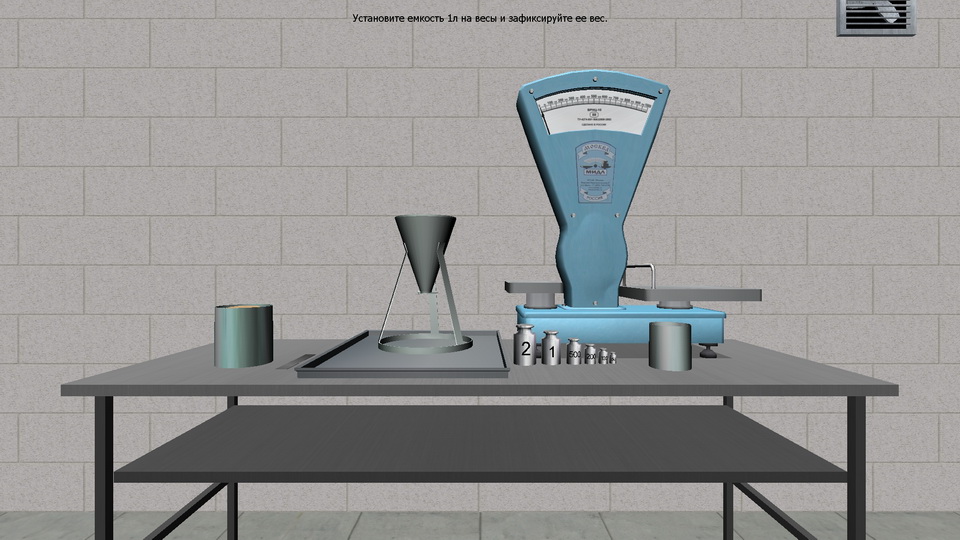

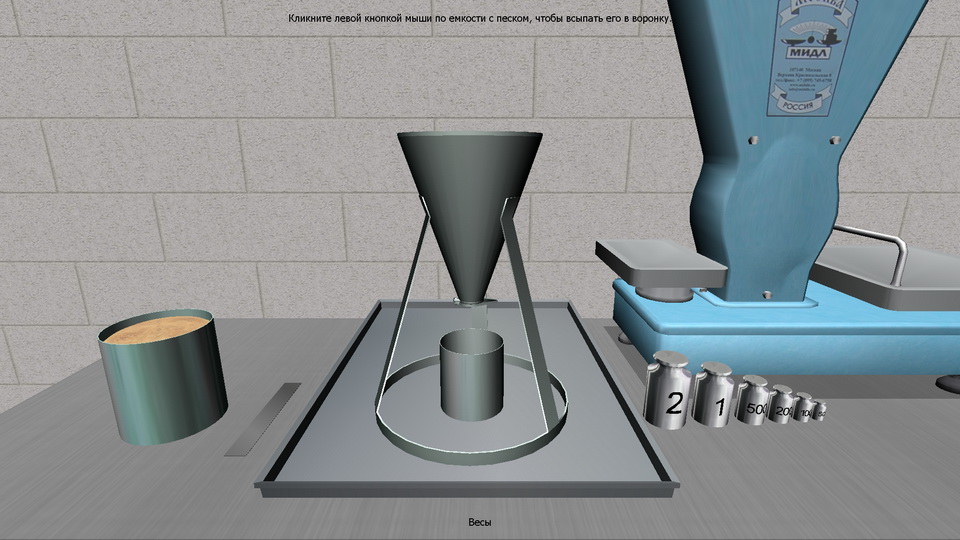

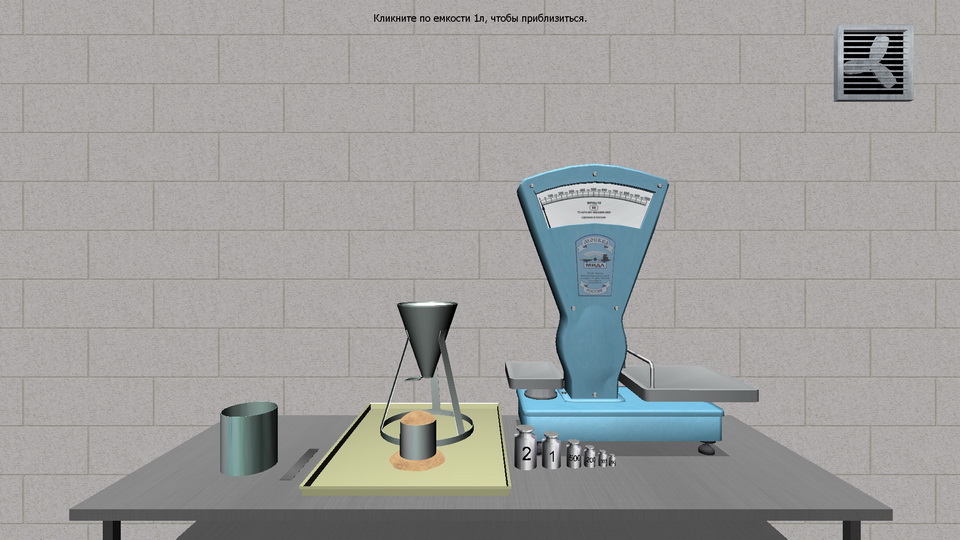

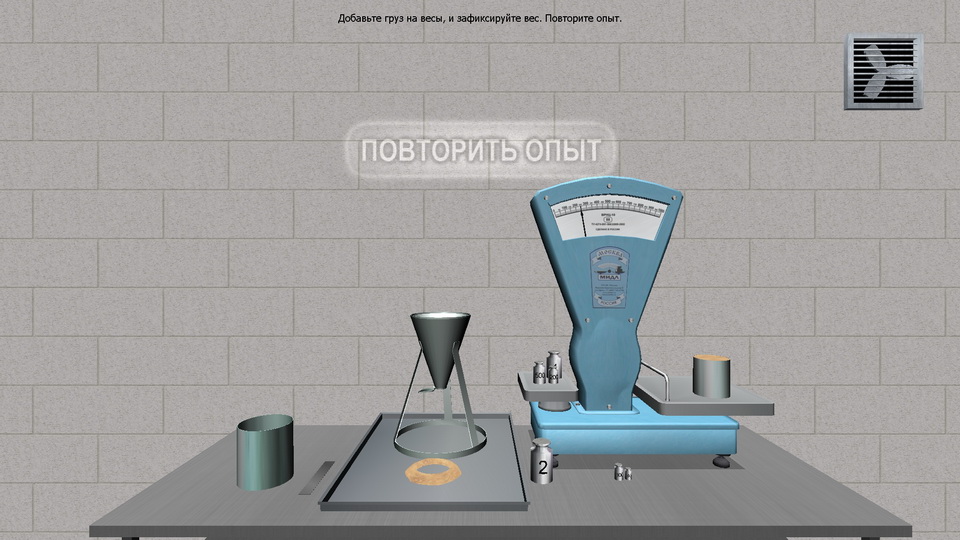

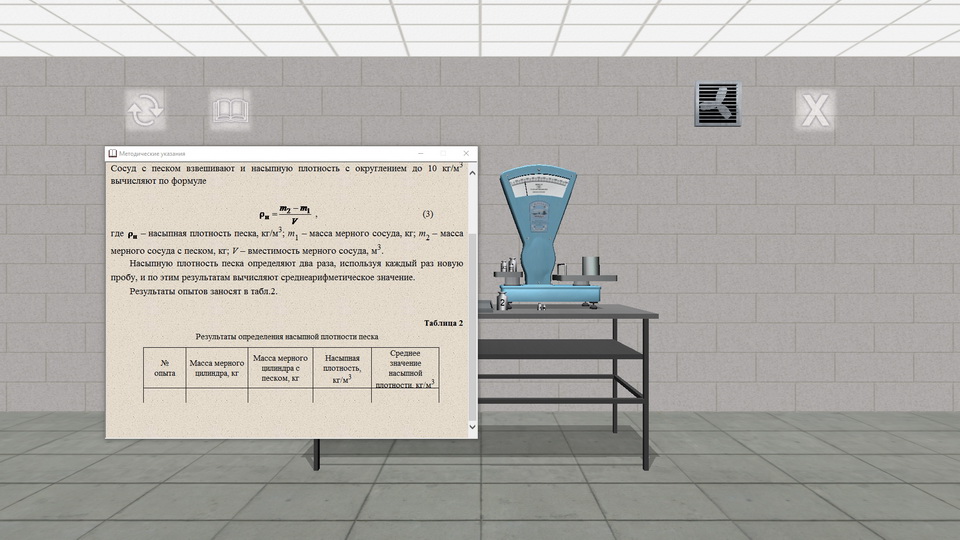

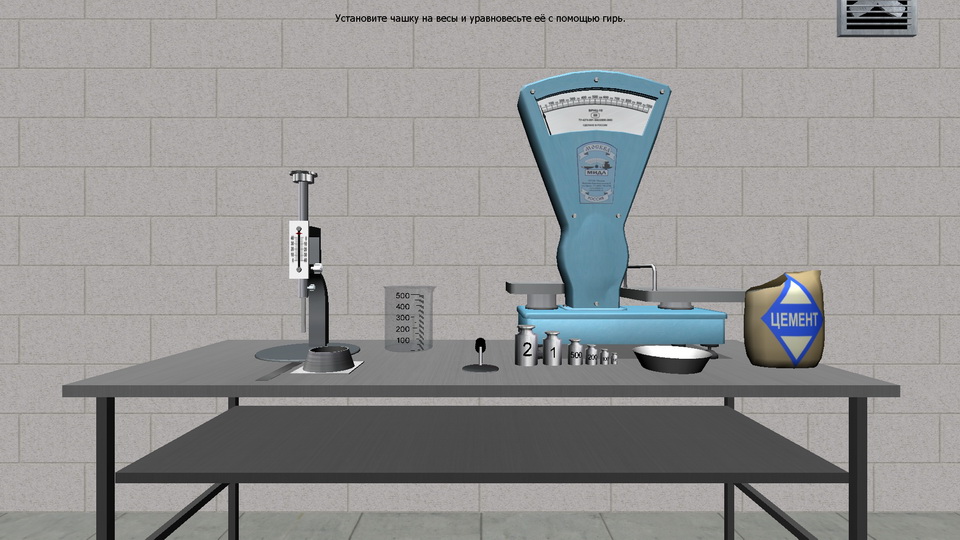

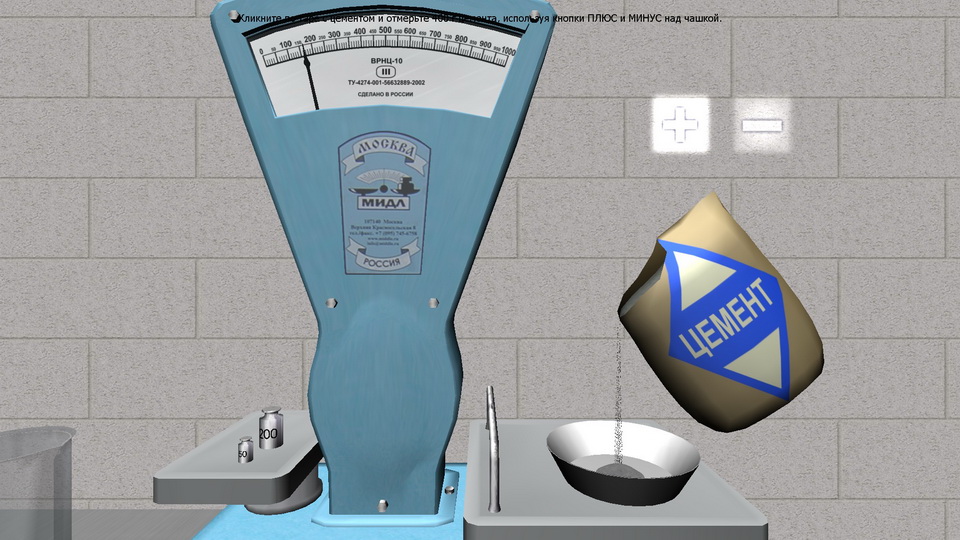

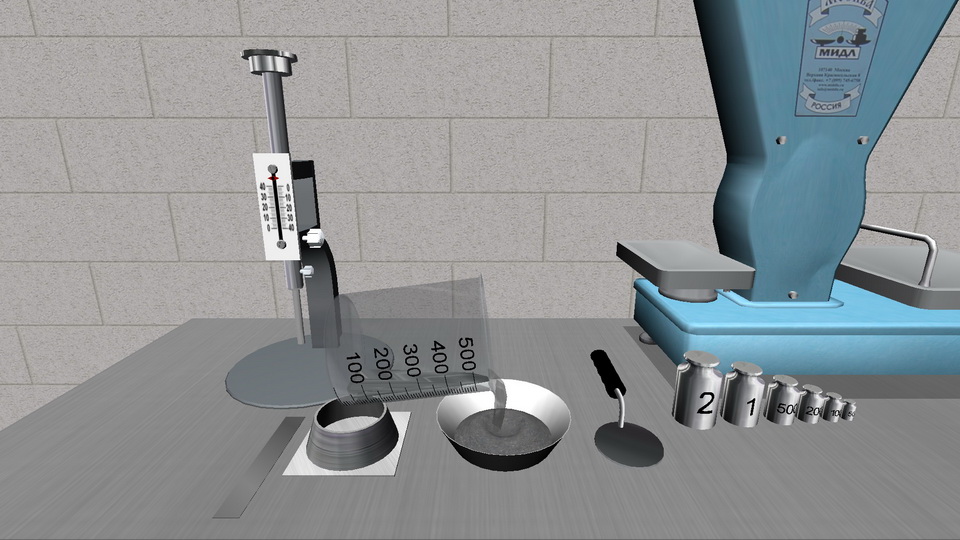

OBJECTIVE: The determination of the bulk density of quartz sand. SUMMARY: The main element of a laboratory installation is a metal cone-funnel, through which a sample of bulk material (sand) is passed. The main task of the experiment is to determine the density of sand in a loose-bulk state. The input parameters of the experiment are the masses of cargo that balance the measured capacity for weighing sand. The output parameter of the experiment is the mass of sand in the tank after backfilling.

OBJECTIVE: The determination of the normal density of cement paste using the Vicat device. SUMMARY: In laboratory work, the normal density (consistency) of freshly prepared cement paste is examined using a standard Vicat device, equipped with a special metal pestle of a certain diameter. In the process, the stages of preparing cement paste from raw materials are simulated. The input parameters of the experiment are: the mass of cargos, balancing the capacity for mixing the dough and the volume of water added to the cement. Output parameter – the depth of the pestle immersion of the Vicat device in the cement paste.

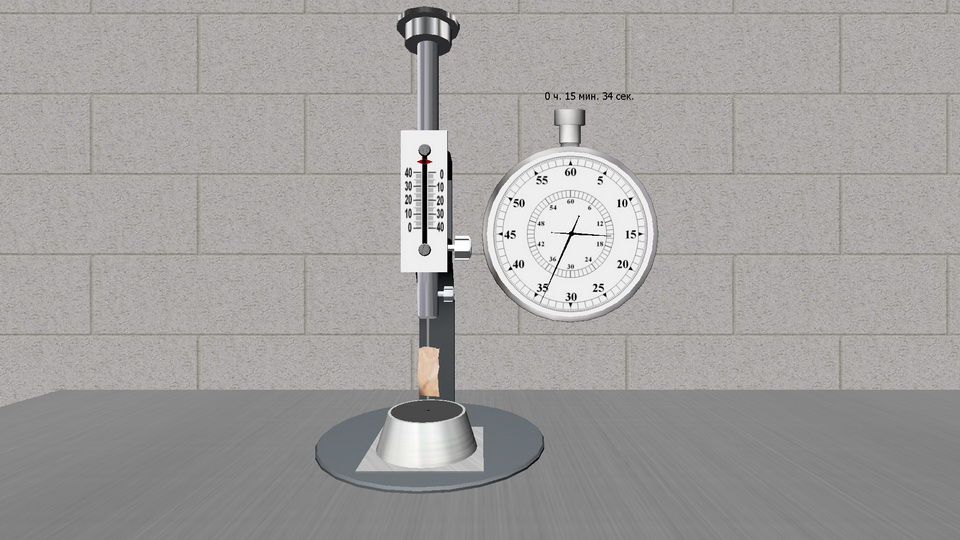

OBJECTIVE: The determination the setting time of cement paste using the Vicat device. SUMMARY: The test is carried out using a standard Vicat device, equipped with a thin metal needle. During the test, a ring-shape with cement paste is installed on the Vicat device platform, after which the needle is immersed in the cement paste with a certain time step. At each immersion, the depth of the lowering of the needle into the cement paste is measured. The input parameter of the simulation experience is the time of measure the depth of immersion of the needle of the Vicat device into the cement paste. The output parameter of the experiment is the depth of immersion of the needle of the Vicat device into the cement paste. According to the test results, the time of the beginning and end of the cement setting is recorded.

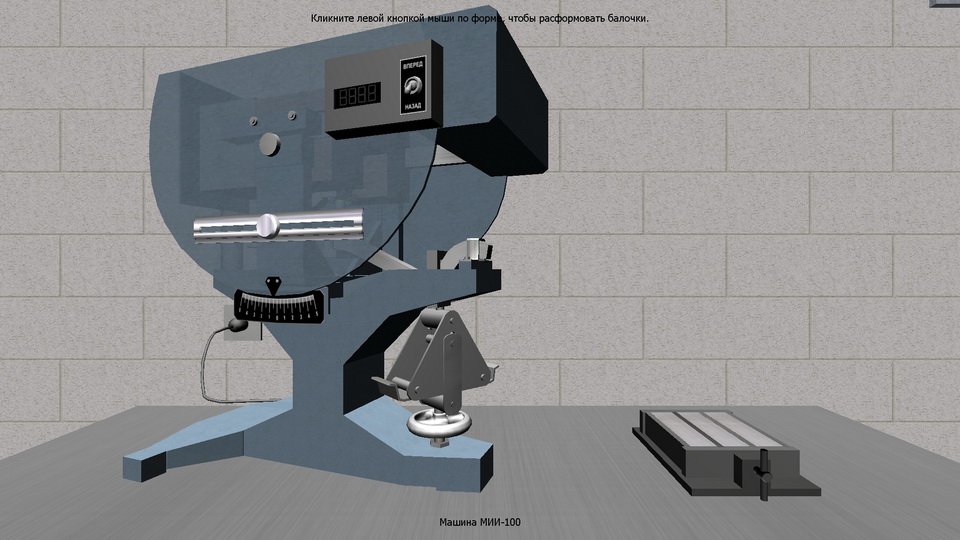

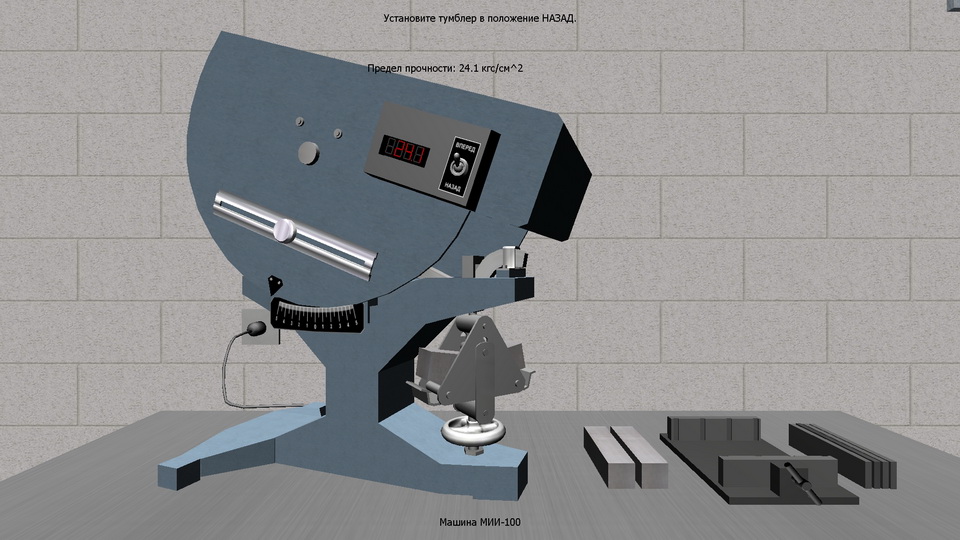

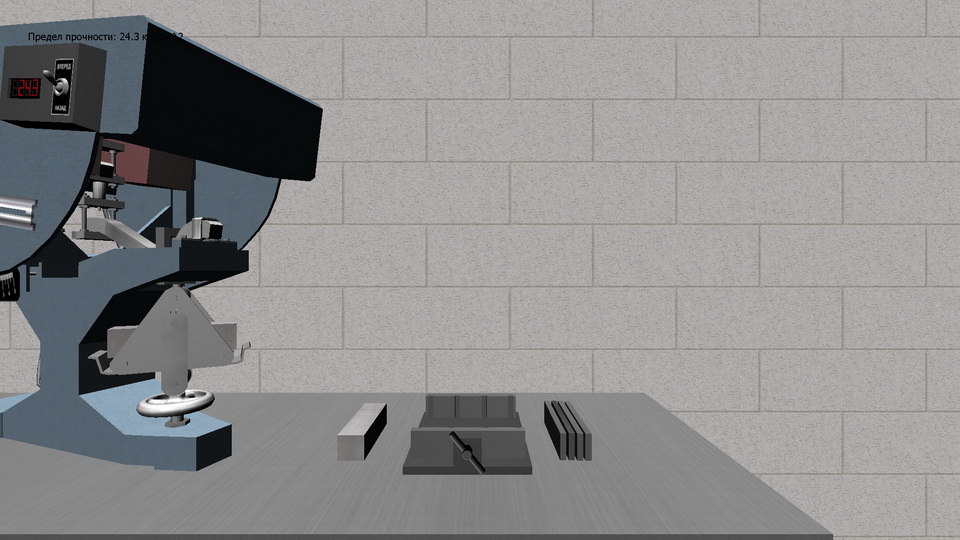

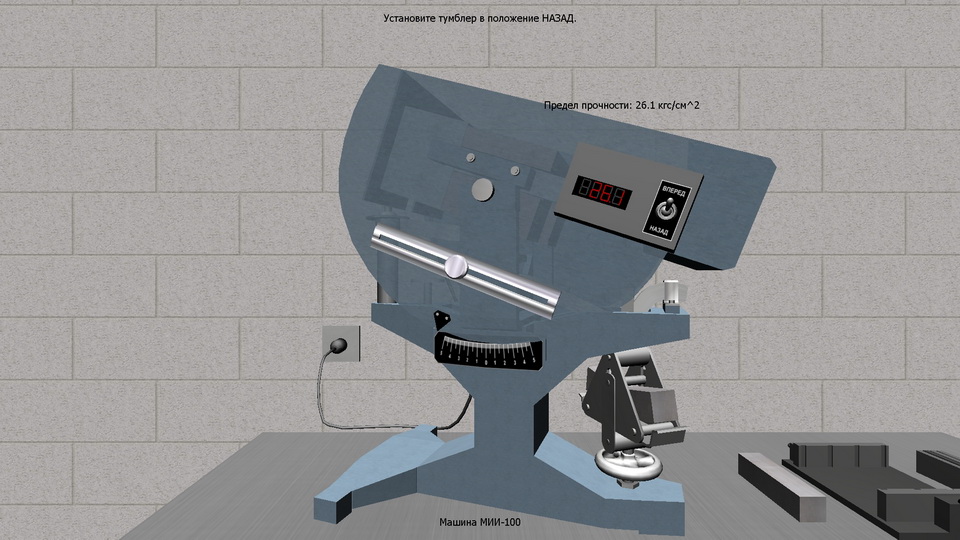

OBJECTIVE: The determination the bending strength of the specimens of beams from fine-grained concrete on a special testing machine. SUMMARY: The test is carried out on a special testing machine, the main element of which is the mechanical seizure of Michaelis. Concrete samples in the form of rectangular beams are alternately mounted in a mechanical grip and a smooth loading of the sample is made until its destruction. The input parameter of the simulation experience is the number of the selected test specimen-beam. The output parameter of the experiment is represented by the value of the tensile strength of concrete during bending, taken from the indicator of the testing machine.

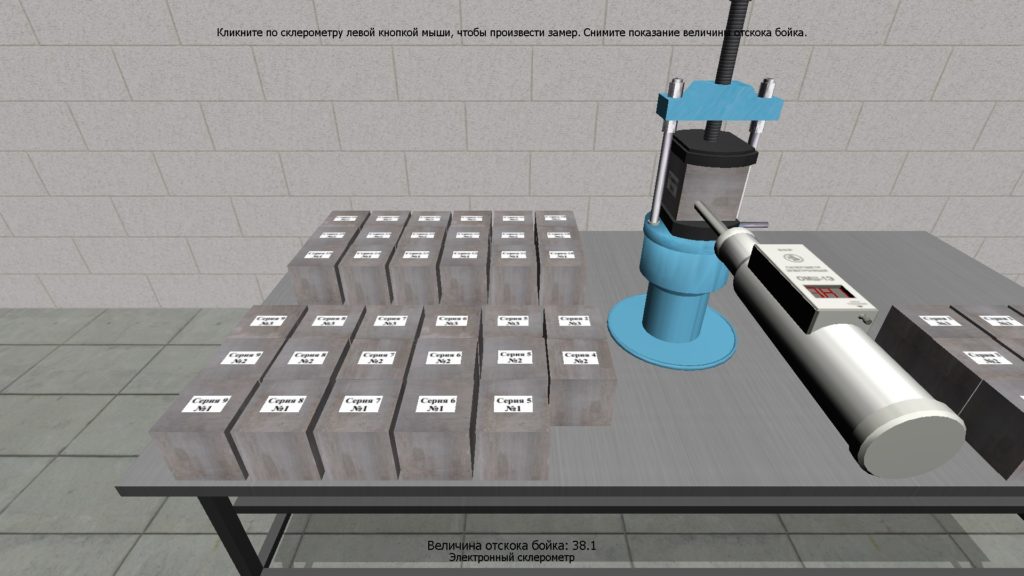

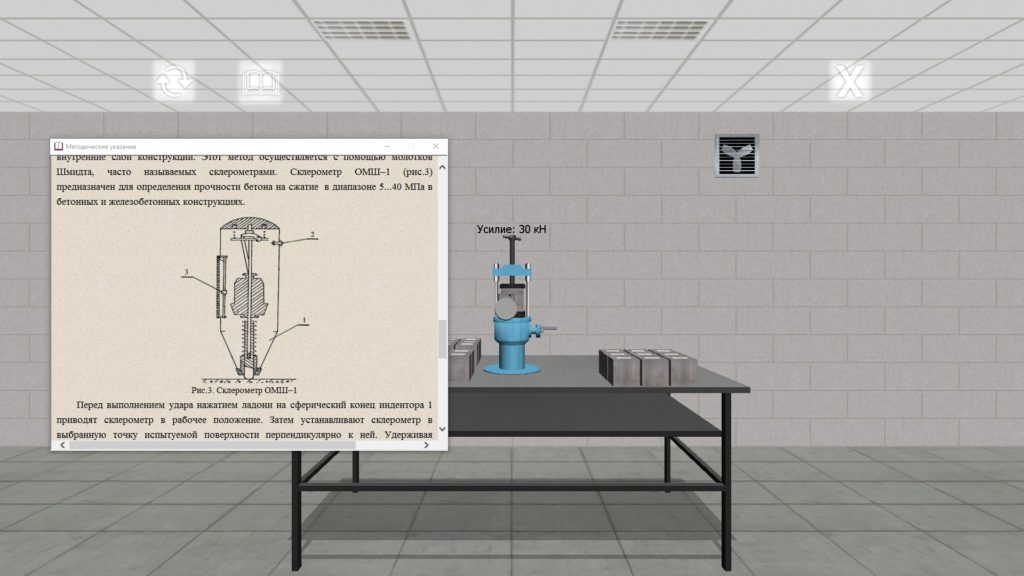

OBJECTIVE: The determination of the strength of concrete by non-destructive method using an electronic sclerometer. SUMMARY: The strength of cubic concrete samples is determined using an electronic sclerometer equipped with an electronic display. The input parameter of the simulation experience is the number of the selected test sample-cube of concrete. The output parameter is the magnitude of the rebound of the sclerometer striker.

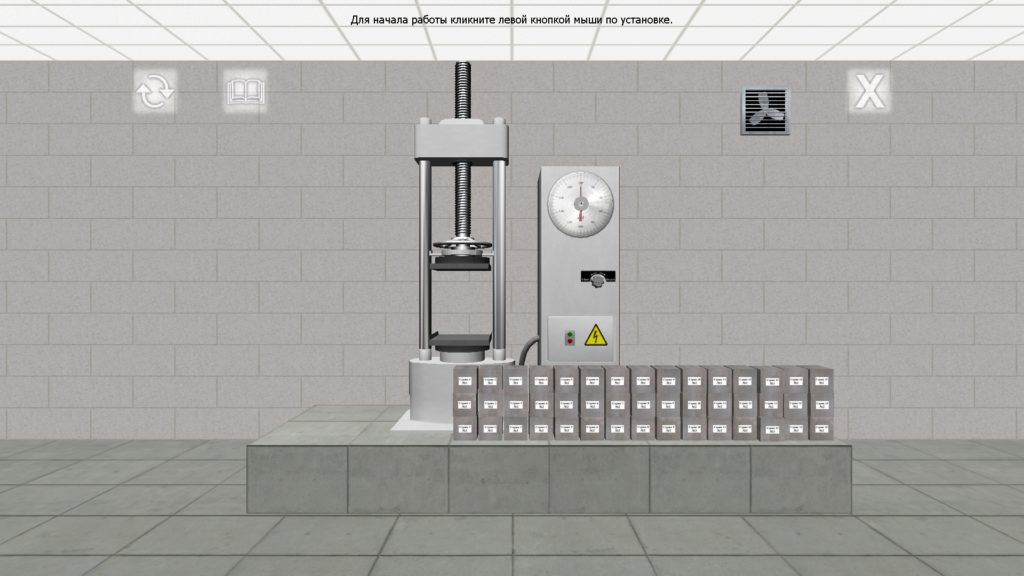

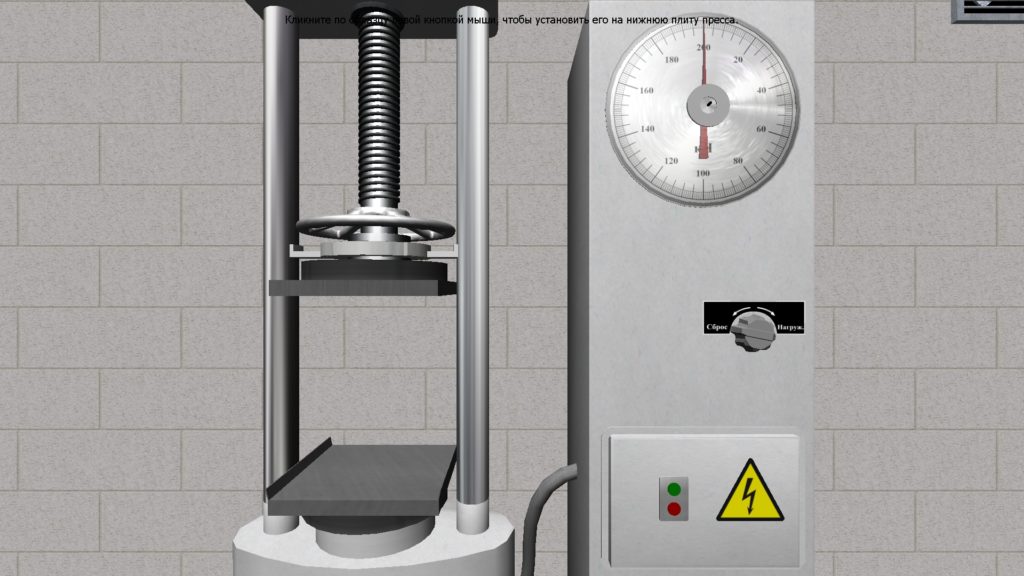

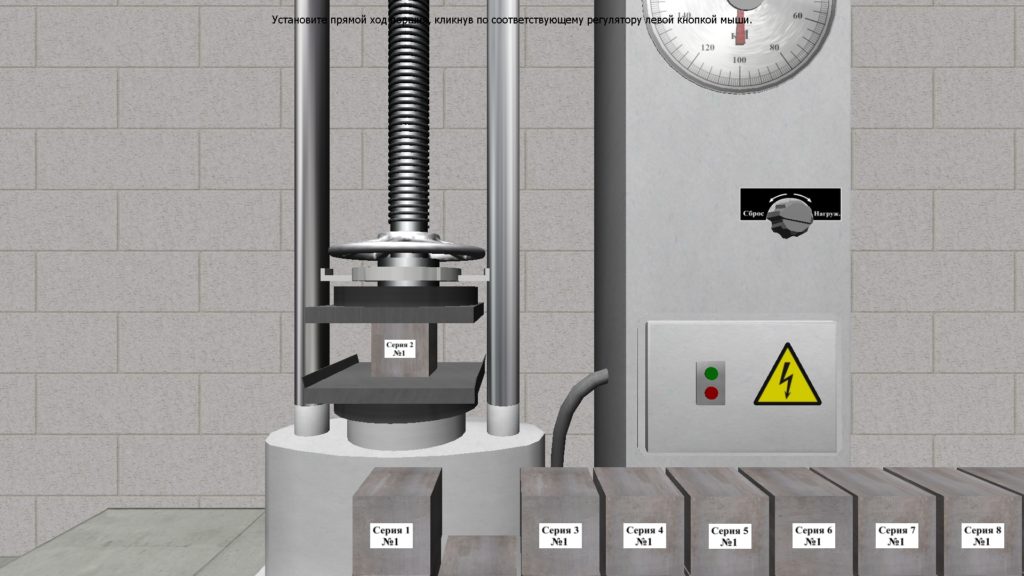

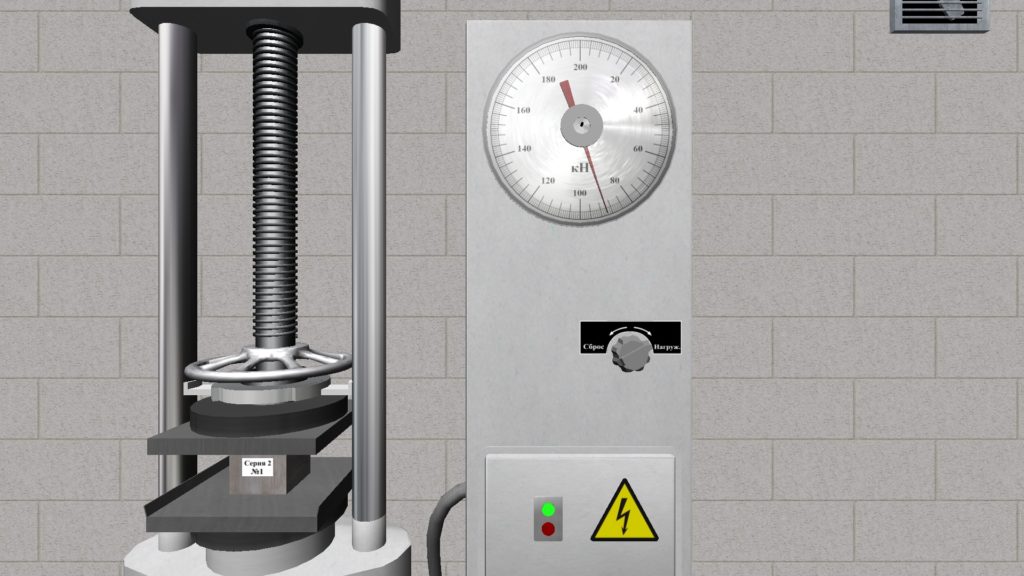

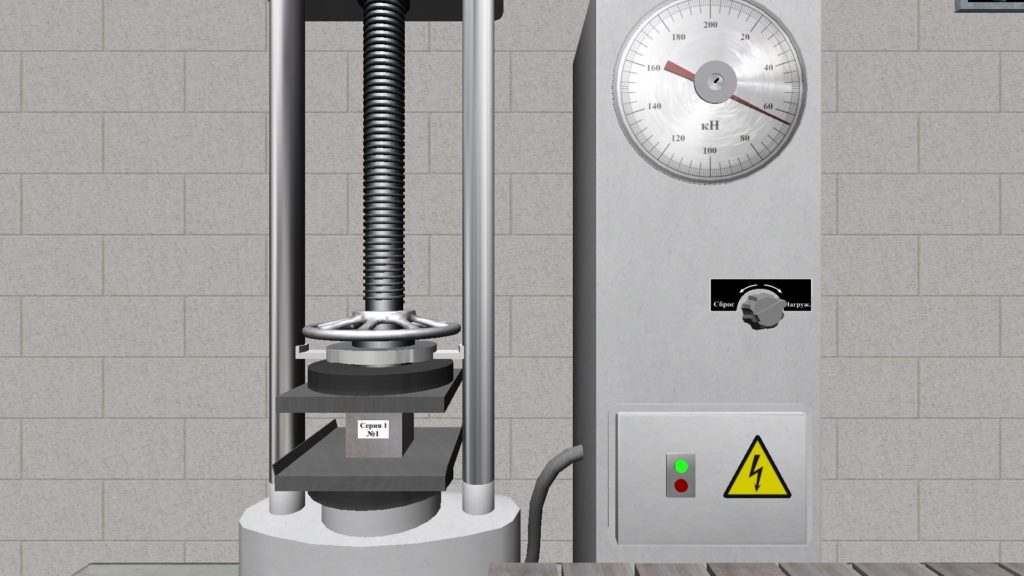

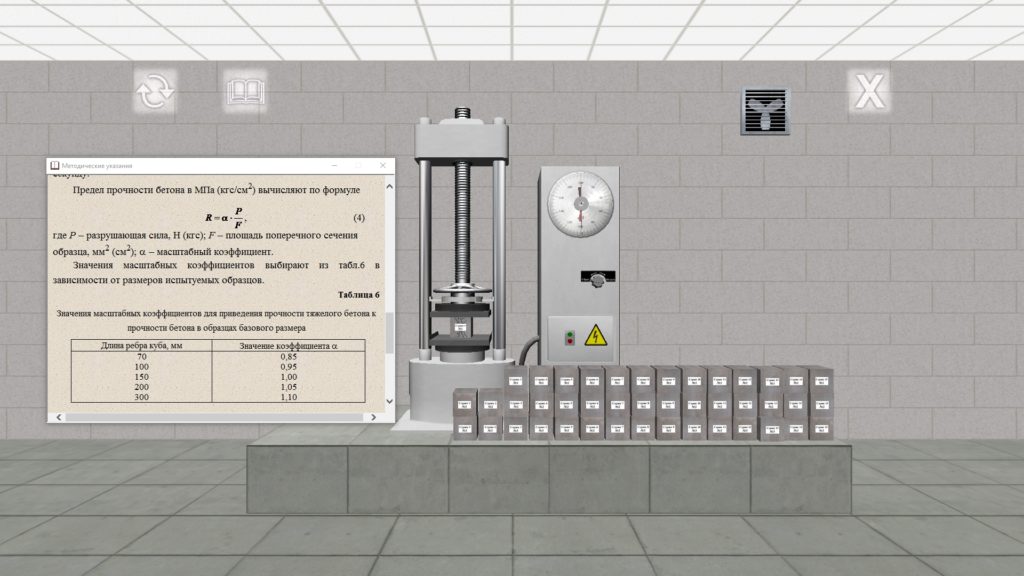

OBJECTIVE: The determination the compressive strength of concrete using a laboratory hydraulic press. SUMMARY: The laboratory stand is represented by a hydraulic press with a maximum load of 200 kN. In the process of performing the work, standard samples of concrete of cubic form are tested. The input parameter of the simulation experience is the number of the selected test sample-cube of concrete. The output parameter is the value of the effort of destruction of the sample under the loading plate of the hydraulic press in kN.