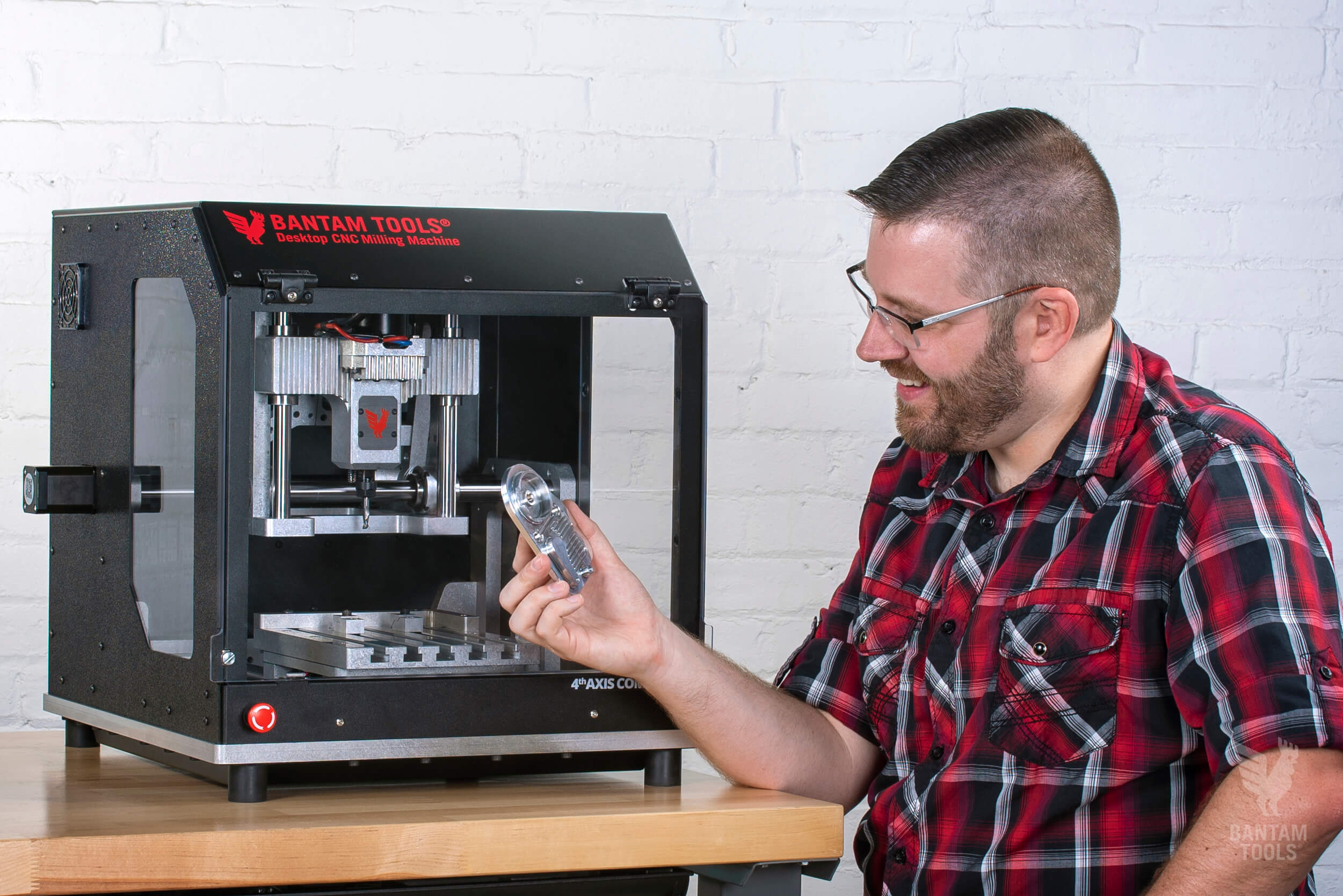

The Bantam Tools Desktop CNC Milling Machine is an affordable, proven prototyping solution that empowers you to machine aluminum parts fast and easy. With 4th axis compatibility, 1/4” tooling, a 7” x 9” x 3.3” build volume, and a 28,000 RPM spindle, this desktop CNC sets the standard for desktop machining and empowers you to make pro-grade, precision parts. Every Bantam Tools Desktop CNC Milling Machine comes with a fully enclosed powder-coated steel frame, built-in E-stop button, and a free version of our intuitive Bantam Tools Milling Machine Software, making it a great choice for any shop, lab, studio, or makerspace.

The Bantam Tools Desktop CNC Milling Machine can comfortably hit a material removal rate (MRR) of 0.4 cubic in/min (10.16 cubic mm/min) in aluminum 6061 and has a repeatability of +/- .001”, enabling you to make functional parts quickly. Other soft metals such as brass and copper, engineering plastics, hardwoods, machining wax, and FR-1 are also supported.

Pull your Bantam Tools Desktop CNC Milling Machine right out of the box, plug it in, and start milling. The machine is clean, fully enclosed, and comes with built-in safety features, including a physical E-stop button, safety interlock door, and safety windows.

Our robust ecosystem of CNC accessories seamlessly integrate with the Bantam Tools Desktop CNC Milling Machine and Milling Machine Software, giving you the flexibility to take on any job. We offer vises, a fixturing pallet, PCB spoilboard, 4th axis accessory, vacuum and air blaster attachments, and more.

The intuitive Bantam Tools Milling Machine Software makes setting up and running your job easy. G-code integration is standard and the free version of our software is packed with powerful features including:

The Bantam Tools software is compatible with both Windows and Mac operating systems. For Mac users, the Bantam Tools software is compatible with the M1 chip. The included free version of our Bantam Tools software supports the following file types:

Our customers are building the future they want to see. For them, CNC machining isn’t just a mode of fabrication, it’s a way of life. Our world changers are at the forefront of industries, such as aerospace, biomedical, defense, sustainable energy, robotics, you name it. While skill builders like Microsoft, Bridgerland Technical College, MIT, UCLA, and more have added our desktop CNC machines to their labs and classrooms to close the skills gap.